Facilities

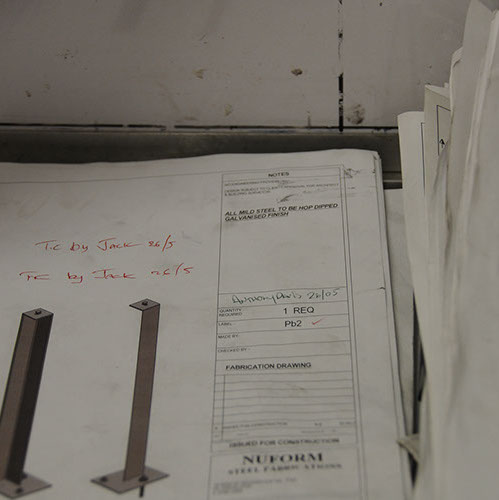

NuForm Steel Fabrications Pty Ltd is located in Bayswater, Victoria, Australia.

NuForm has its own plant and equipment to ensure that jobs are completed on time and within budget.

NuForm have an area of around 5,000 meters squared of floor space with suitable access for large constructions.

NuForm have a secure caged “holding bay area” for outgoing work if needed.

These facilities include in the workshop:

<

>

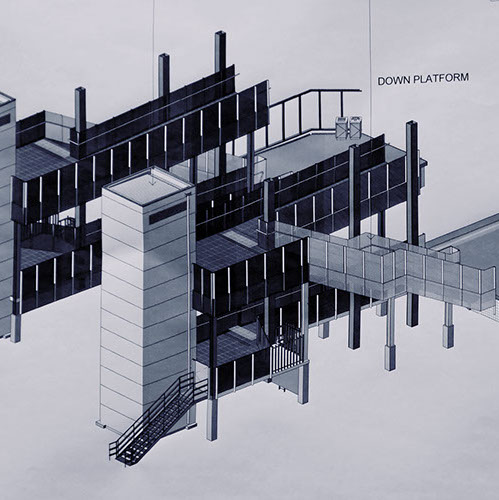

NuForm are in the business of Detailing, Fabricating and Installing custom made Steel, Steel and Glass, Aluminum, Stainless Steel and other new age materials and components to form Architectural Structures.

NuForm provide subcontract fabrication services to address the needs mainly of Large Corporate Companies that win large infrastructure contracts with their Architectural Intent submissions.

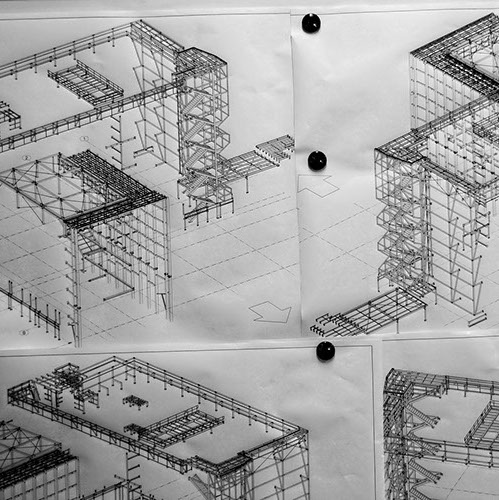

These winning bids for infrastructure provide information at a level to satisfy and win the bid however the level of detail is insufficient for fabrication taking into account the available fabrication facilities and cost effective fabrication.

A structure is an arrangement and organization of interrelated elements in a material object or system, or the object or system so organized. Material structures include man-made objects such as buildings and machines and natural objects such as biological organisms, minerals and chemicals.

To date NuForm have detailed fabricated and installed panels, balustrades, walls, brackets and fixtures using a variety of materials and processes.

NuForm use off the shelf 3D Advanced Software such as Autodesk Inventor to provide their Workshop and Suppliers with detailed fabrication drawings.

The configuration and the variety of these structures has become increasingly difficult to fabricate and the challenge is for NuForm to move forward and introduce more advanced technologies in 3D, Visualization, RFID tracking and sensors and Internet of Things, Big Data from the Cyber Physical world to advantage.

This has led to a reputation as a multidisciplinary and innovative company that is prepared to accept challenges and exceed the expectations of its clients. We pride ourselves on developing working relationships with contractors and suppliers to ensure the best results for our clients.

NuForm are on a continuous improvement program, which includes a collaborative agreement with Swinburne University to provide technological up-skilling to the workforce, together with research and development access to future manufacturing practices.

To achieve this NuForm has signed a collaboration agreement with Swinburne University of Technology. This agreement allows for collaboration from the trade and TAFE level providing a pathway through to Research and Development with the University Advanced Manufacturing Centre.

NuForm and Swinburne have managed to attract funding from Federal Government under the AusIndustry Innovations Connections Program.

NuForm and Swinburne will be engaged in an advanced 3DVisualtion with Integrated RFID tracking over an expected period of several years.

It is hoped that this will provide NuForm with advanced tools to differentiate their offering to customers resulting in reduced time lost on site and greater coordination between the Detail Office, The Workshop and those On Site.

Under the direction of Professor Bronwyn Fox at the Swinburne University Advanced Manufacturing Centre are working with the NuForm Steel Fabrications Research Project Manager Terence Polkinghorn (Advisor to Nuform) and Lady Garzon the appointed Research Associate to undertake the research and development on the project.

Consideration will be given to compliance with BIM standards during the project.